Comparing the different types of filter belts available in the market

comparing the different types of filter belts available in the market

Sludge dewatering with filter belts: Comparing the different types of belts available in the market

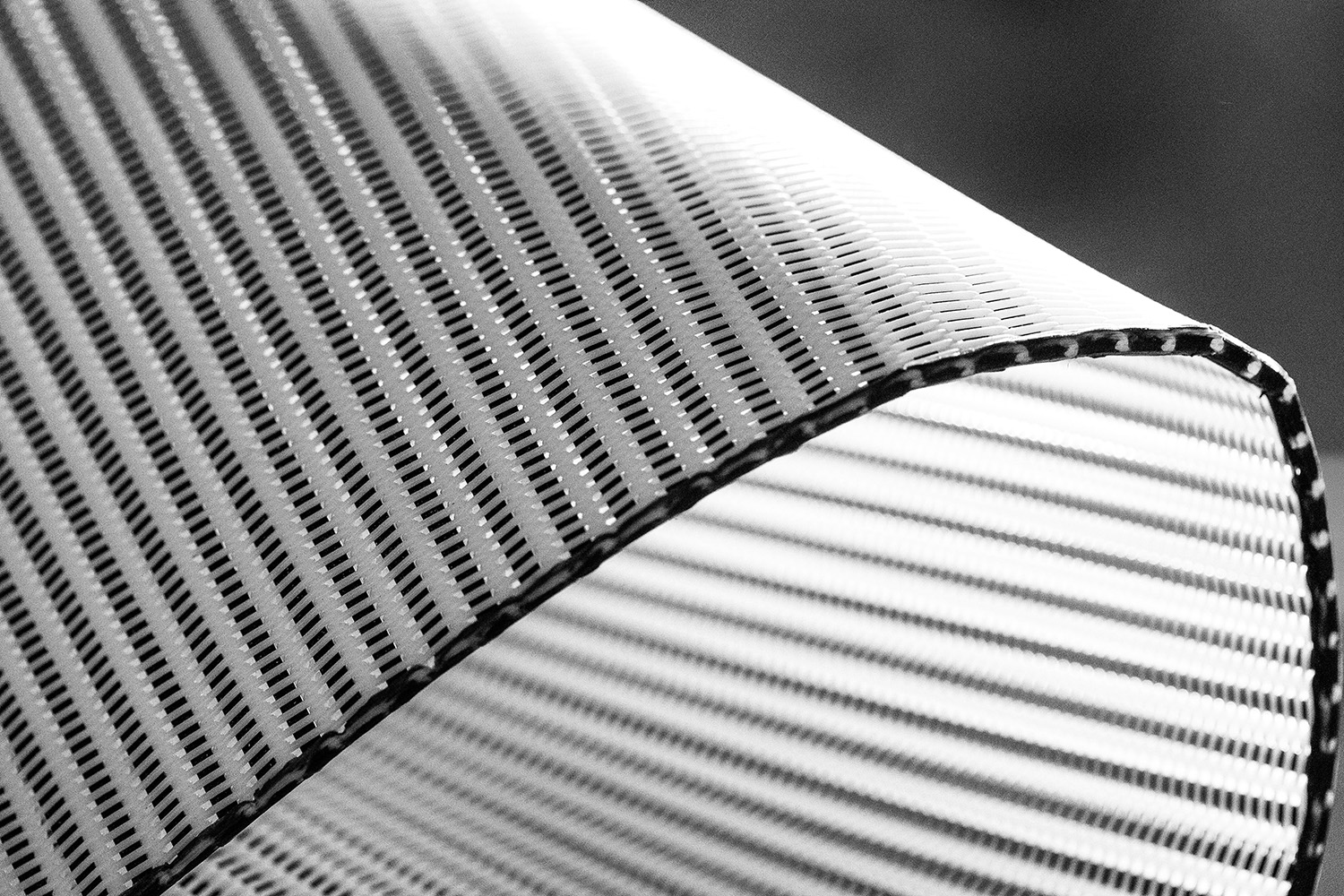

Sludge dewatering with filter belts is a common process used in the wastewater treatment industry to reduce the amount of waste generated from the treatment of industrial and municipal wastewater. Filter belts are a critical component of the sludge dewatering process, and selecting the right type of belt can have a significant impact on the overall efficiency and effectiveness of the process. In this article, we will compare the different types of belts available in the market for sludge dewatering and help you choose the right belt for your specific application.

Polyester filter belts

Polyester filter belts are one of the most widely used types of belts in the market due to their excellent filtration performance and high chemical and temperature resistance. These belts are made from a strong, durable polyester material, making them suitable for demanding applications that require frequent cleaning or handling of heavy loads. Polyester filter belts are commonly used in municipal wastewater treatment, food processing, and mining industries.

Polypropylene filter belts

Polypropylene filter belts are an excellent choice for sludge dewatering applications that involve low to moderate temperature and chemical exposure. These belts are known for their low moisture absorption and good resistance to acidic and alkaline chemicals, making them ideal for the removal of sludge from industrial wastewater. Polypropylene filter belts are commonly used in the chemical, pharmaceutical, and wastewater treatment industries.

Nylon filter belts

Nylon filter belts are an excellent choice for sludge dewatering applications that require a high level of abrasion resistance. These belts are made from a high-strength nylon material that offers excellent tensile strength and abrasion resistance. Nylon filter belts are commonly used in applications that involve dewatering abrasive and gritty sludge, such as the mining and quarrying industries.

PTFE (Teflon) Filter belts

PTFE (Teflon) filter belts are an excellent choice for sludge dewatering applications that involve high-temperature exposure and corrosive chemicals. These belts are made from a highly resistant PTFE material that offers excellent chemical and temperature resistance. PTFE filter belts are commonly used in applications that involve high-temperature drying, such as the chemical, pharmaceutical, and food processing industries.

Conclusion

Selecting the right filter belt for your sludge dewatering application is critical to ensure maximum efficiency and effectiveness of the process. With different types of filter belts available in the market, each offering unique properties and benefits, it’s important to consider the specific requirements of your application when choosing a filter belt. By understanding the advantages and limitations of each type of filter belt, you can make an informed decision that helps you achieve your sludge dewatering goals.

Sludge dewatering with filter belts

Our portfolio of filter belts offers a wide range of solutions for various sludge dewatering applications. We understand that each industry has unique requirements when it comes to sludge dewatering, and our filter belts are designed to meet these specific needs. Whether you need a belt that can handle high-temperature drying or one that is resistant to abrasive sludge, our portfolio has you covered.

We work closely with our clients to understand their specific requirements and develop customized solutions that offer maximum efficiency and effectiveness. Our commitment to quality and innovation ensures that our filter belts are at the forefront of the industry, delivering exceptional results and helping our clients achieve their sludge dewatering goals.

Arrange a call

Please feel free to send me a message. Either directly by

e-mail or add me to your network on LinkedIn and contact me there. I look forward to meeting you and talking to you about solving your problems.

Address

R+F FilterElements GmbH

Wollenweberstraße 25

31134 Hildesheim

Germany